Well, it’s been a while since I

have done one of these.

Back in December 2016 I put up my Looting Tutorials, after previously appearing on Bell of Lost Souls. After a recent mention on Twitter, I thought I would do a quick Part 4 to cover an additional technique.

Curved Surfaces.

I’ve done this a couple of times

now, including for the Weirdboy Battle Tower turret weapon below. While you can

take thick styrene and bend it through heating, I prefer to build a curved shape

through a series of laminated layers. This gives you more control when creating

the shape and more options for thickness, while resulting in a strong final

piece.

To begin a former is selected, basically a curved item styrene sheet will be wrapped around. The former size will depend on the finished size you want with the former setting the internal diameter, though you can always increase the diameter by adding ‘packing layers’ which are not glued, but this will make things a bit fiddlier. One thing to keep in mind is to select a former with no risk of the styrene bonding to, even if glue spills out (which it will). So resin, metal, wood etc is ideal.

For this example I am making a big, chunky, shoulder pad. Maybe for a Gorkanaut or a similar large walker. However, it could easily be something like a weapon cowling.

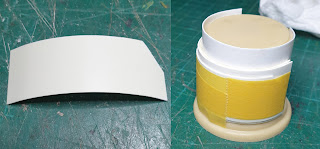

A resin plinth was selected for the former with 0.5 mm styrene sheet selected for the layers.

Thicker styrene could be used, for less layers, but the thicker you go the harder it will be to bend the sheet

resulting in good contact and a good bond between layers.

The first layer is bent around the former and tightly taped into position, you do not want any gaps between this layer and the former. I tend to give it a bit of a curve to stop with, more useful with thicker layers as 0.5 mm should be easy enough to bend round any former you use.

|

| Former with the first layer taped to it |

Taking a second piece of styrene thick polycement is liberally applied on the inside face, it is then firmly taped in position over the base layer. I always use thicker glue as thin polycement will quickly start evaporating resulting in an inconsistent bond.

The process of gluing and taping layers in place is repeated until you have the thickness you desire – minus the final layer. For the shoulder pad I added three layers giving me a total thickness of 2 mm before the final layer was added.

Unlike the previous layers the last layer is precut to the final size and shape desired. Here we have a rectangular piece with a chamfered corner. For the Weirdboy Battle Tower I used a rectangle with rounded corners.

|

| Final layer, cut to shape and glued in place. |

It is glued in place in the same way, but greater care is taken so that the edge of the piece was parallel to the former base, if you don’t do this the final piece will be skewed.

The glue can then be given some time to fully dry. Once dry all the tape can be removed, allowing the styrene piece to simply slide off the former.

|

| The piece removed from the former. |

The styrene can now be cut back to match the final, pre-shaped, layer. With an Orky build you don’t need to worry about being too precise. As I trim back the styrene I distress the edges with chips, cuts etc. If needed a bit of GS or putty can be used on the the edges at any points where the layers are noticeable.

|

| Final piece, trimmed back and distressed. |

You now have the finished curved part which can be detailed in any way you want before adding any addition parts to allow it to be mounted onto the model.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.